A scientific exploration of the technical aspects behind perfect espresso milk foam

Milk frothing is a fundamental technique in the preparation of espresso-based beverages such as lattes, cappuccinos, and macchiatos. While it may appear simple, the process involves complex physical and chemical interactions that transform ordinary milk into a velvety, creamy microfoam that enhances both the texture and flavor of coffee drinks.

This website explores the technical aspects of milk frothing, focusing on the physics and chemistry that make it possible. From milk composition to protein behavior, temperature effects to bubble formation, we'll dive deep into the science behind perfect milk foam.

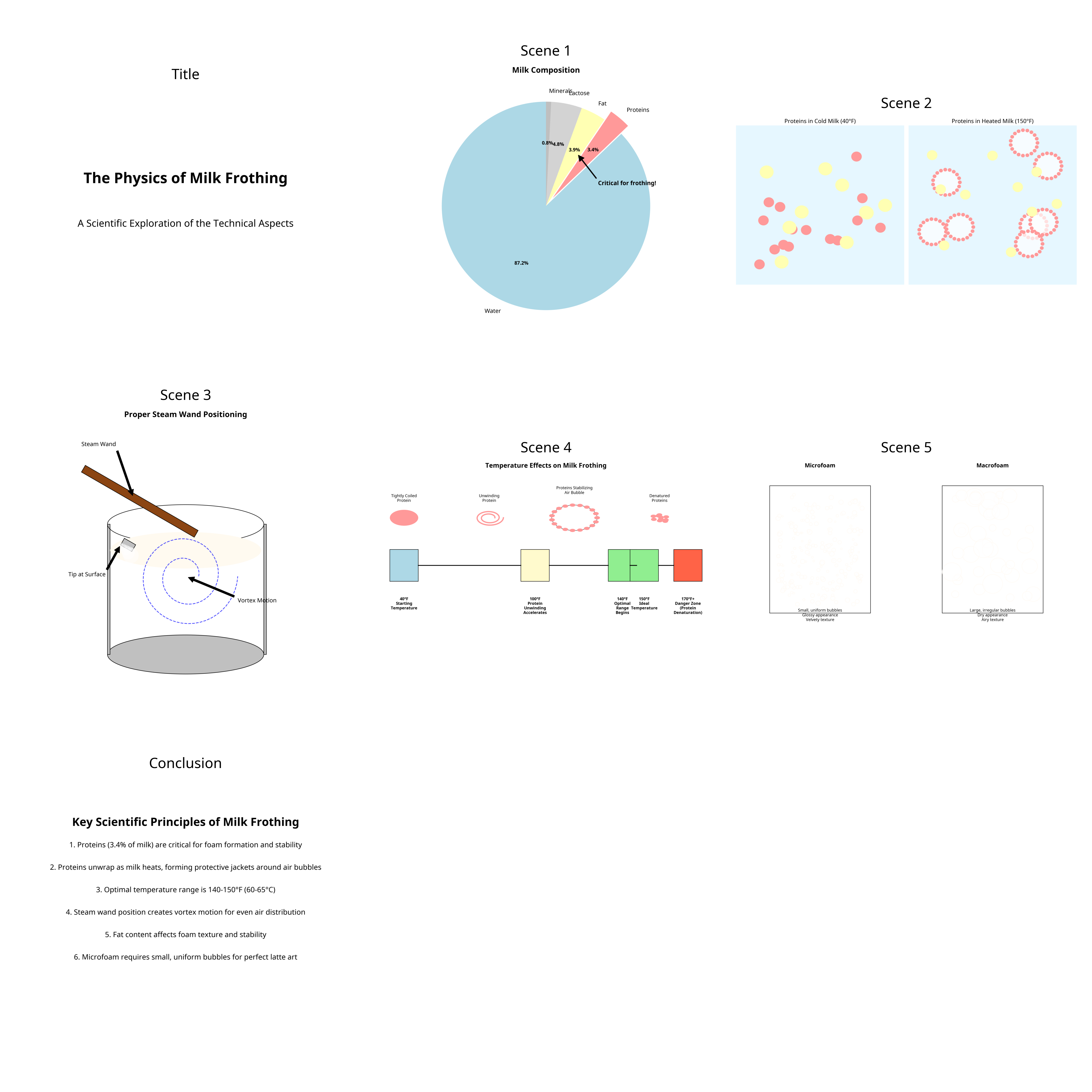

Understanding milk frothing begins with understanding milk's composition. Milk is a complex biological fluid with several key components that affect its frothing properties:

Water serves as the primary medium in which all other components are dissolved or suspended. It accounts for approximately 87.5% of milk's volume (range: 85.5-89.5%).

Proteins are crucial for foam formation and stability. They account for about 3.4% of milk's volume (range: 2.9-5.0%) and can be divided into two main categories:

Proteins play a critical role in foam formation because of their amphiphilic nature—they have both hydrophobic (water-repellent) and hydrophilic (water-attracted) sides. This dual nature allows them to form a protective layer around air bubbles, stabilizing the foam.

Fat accounts for approximately 3.9% of milk's volume (range: 2.5-6.0%). In non-homogenized milk, fats float around in various sized globules, often combining into a fat cap at the top. Homogenization breaks up these globules into uniform droplets and disperses them evenly throughout the milk.

Fat has a complex relationship with foam formation. While it can help create a creamier texture, it can also destabilize foam. The hydrophobic part of milk protein is as likely to attach to fat as it is to air, which means more fat in milk results in less air it can hold.

Lactose is milk's primary carbohydrate, making up around 4.8% of its volume (range: 3.6-5.5%). It contributes to milk's sweet flavor when fresh and sour flavor when old (as bacteria breaks down lactose into lactic acid). When milk is heated, lactose enhances the perceived sweetness as longer chain carbohydrates break down into simpler sugars.

Minerals such as calcium and magnesium make up about 0.8% of milk's volume (range: 0.6-9.0%). While they have limited direct effect on frothing qualities, they contribute to milk's overall composition and behavior.

The steam wand on an espresso machine is the primary tool for creating milk foam. Understanding the physics of how it works is essential to mastering milk frothing:

Steam from an espresso machine is hot water vapor at approximately 250-255°F (121-124°C). When this high-temperature steam contacts cold milk (typically around 40°F or 4°C), it provides both the energy (heat) and gas (as it condenses) needed for foam formation.

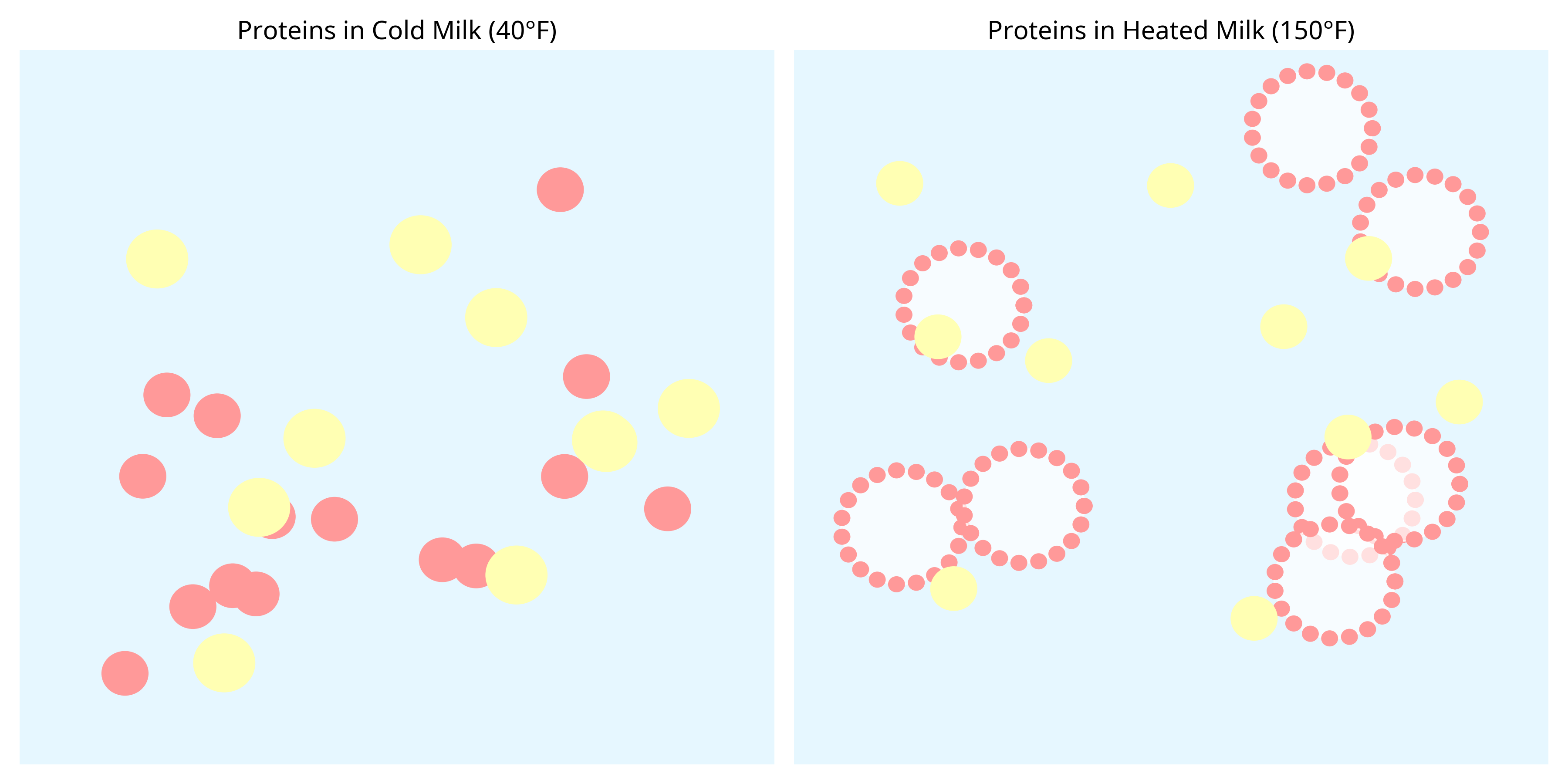

The steam wand produces jets of steam through small holes in the steam tip. These jets act like tiny, fierce whisks when properly positioned. The position of the steam wand is critical:

Proper positioning creates a vortex or whirlpool effect in the milk. This circular motion is crucial because:

The sounds produced during milk frothing provide important auditory feedback about the process:

Experienced baristas use sound as a guide:

The formation of milk foam involves several chemical processes that occur simultaneously during steaming:

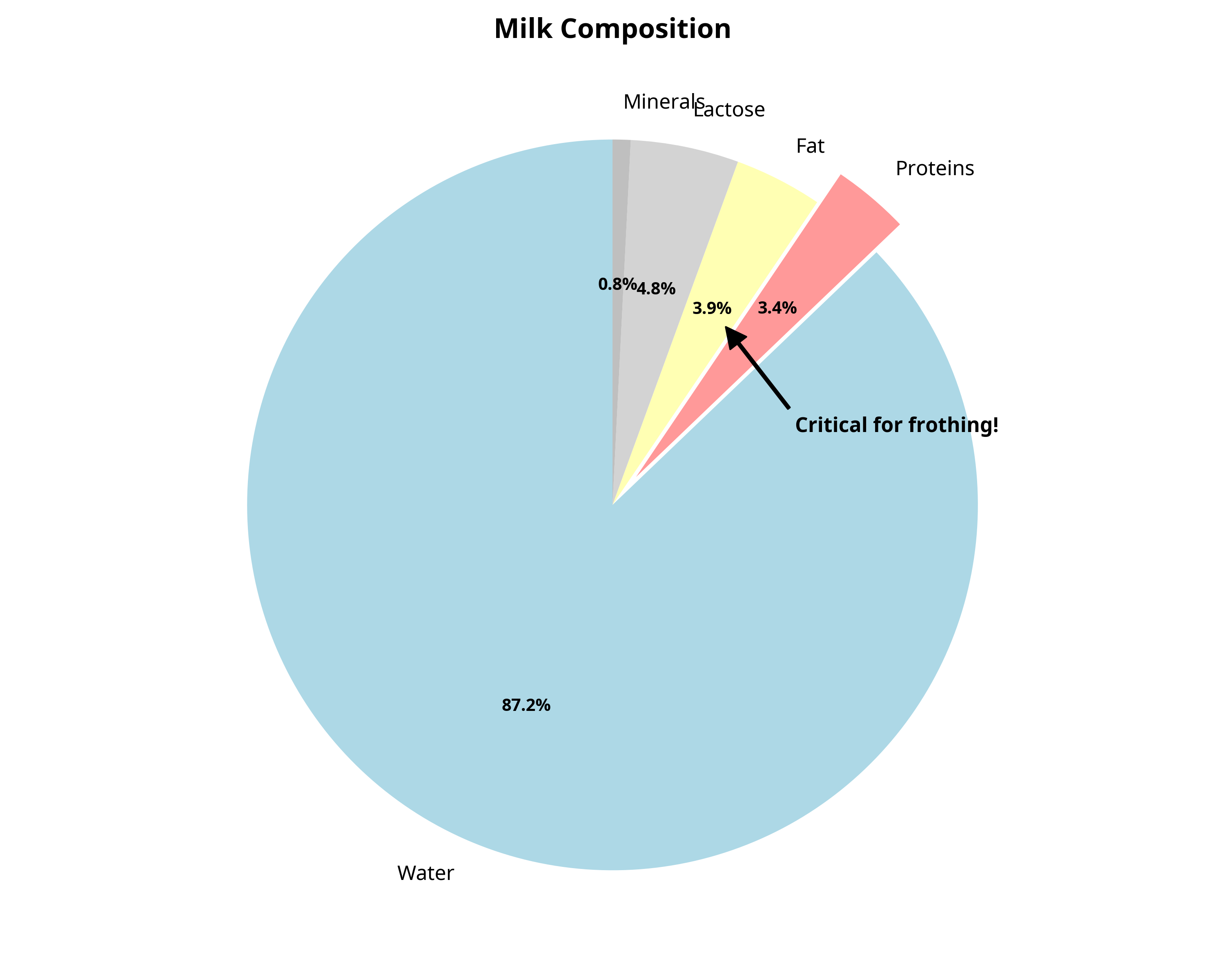

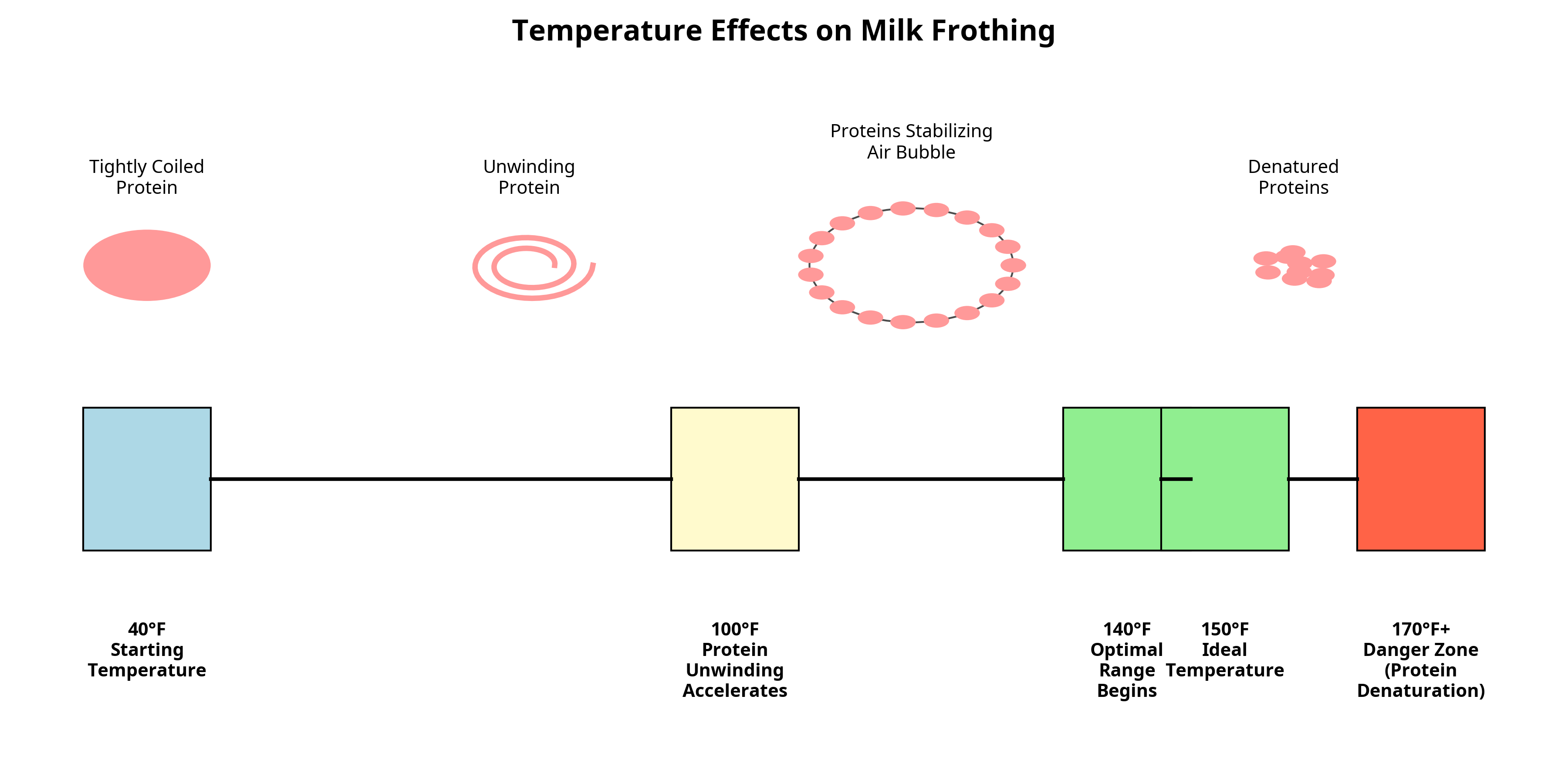

In cold milk, proteins exist in tightly coiled bundles. As milk warms, these proteins begin to unwind (denature) and reorient themselves:

This protein reorientation is temperature-dependent. If milk gets too hot (above 170°F/77°C), the proteins completely break down, releasing the trapped air and ruining the foam.

Air bubbles in milk foam are metastable structures. Their formation and stability depend on several factors:

Fat plays a complex role in foam formation:

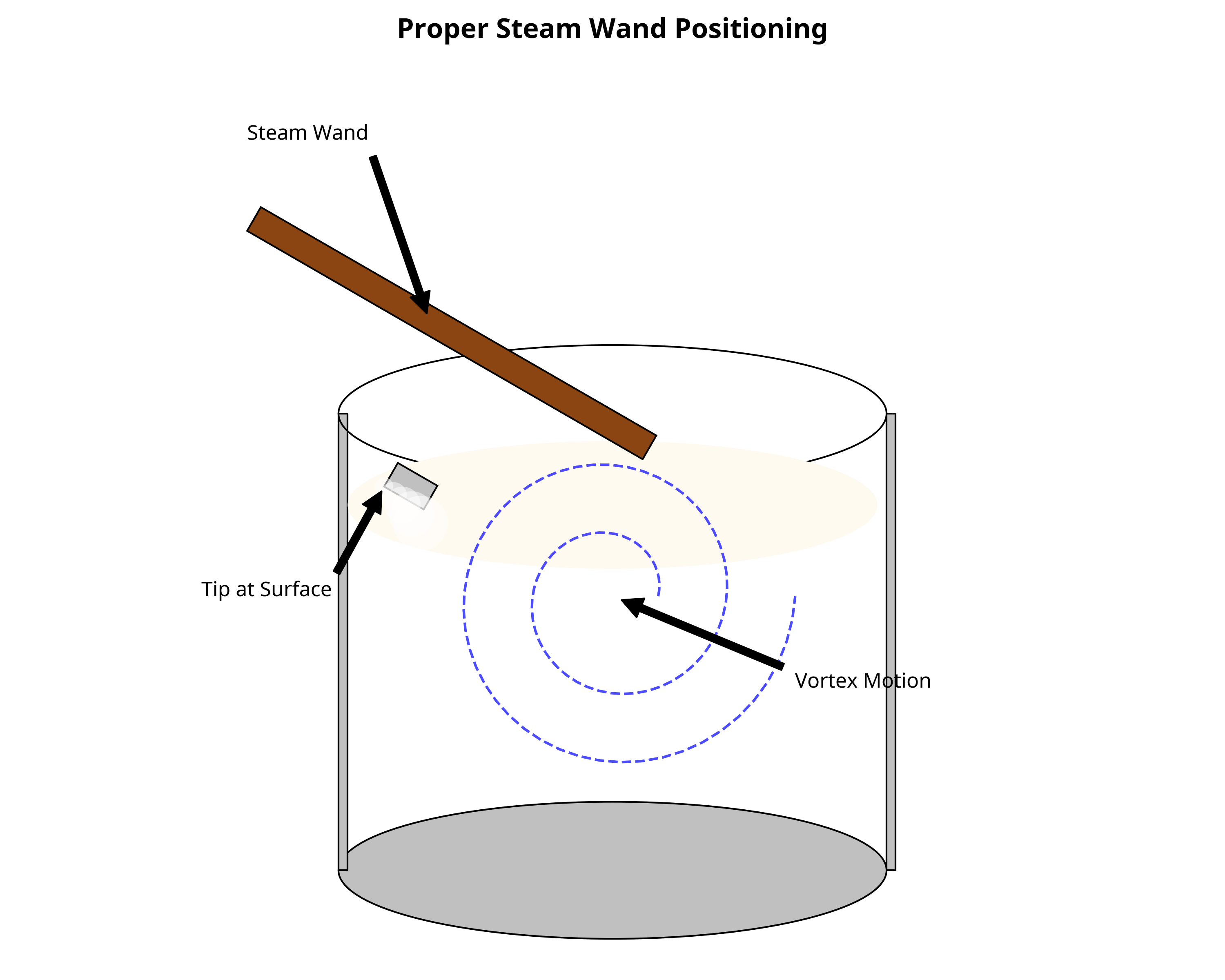

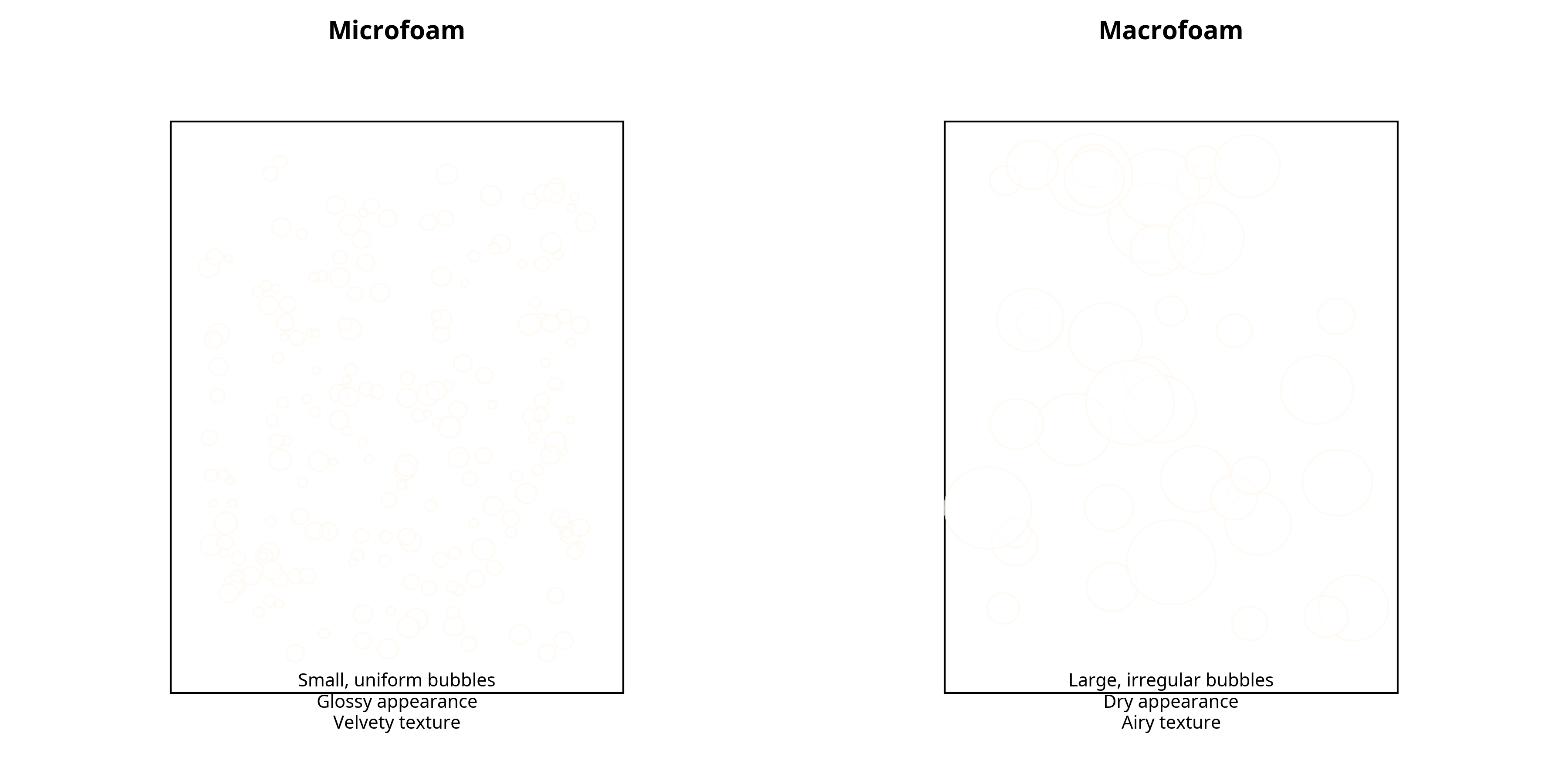

The quality and characteristics of milk foam can vary significantly, with two main categories recognized:

Microfoam is characterized by:

Macrofoam is characterized by:

Temperature plays a critical role in milk frothing, affecting everything from protein behavior to foam stability:

Several studies have confirmed that the foamability of pasteurized whole milk, measured by the volume of foam produced, reaches a minimum at 25°C (77°F). For raw milk, this minimum is around 35°C (95°F).

This dip in foamability occurs due to fat globules consisting of both solid and liquid phases at this temperature. Solid fat crystals in a globule may penetrate the film separating them from the surrounding air, causing spreading of the membrane material which is then adsorbed onto air bubbles.

For pasteurized whole milk, stability increases with temperature up to about 40°C (104°F), then rises steeply until 60°C (140°F), where it starts steadily decreasing.

Different milk types have different optimal temperature ranges:

Different types of milk and milk alternatives have varying frothing properties due to their composition:

Understanding the science of milk frothing leads to several practical techniques for achieving optimal results:

Milk frothing for espresso is a fascinating intersection of physics and chemistry. The process involves complex interactions between proteins, fats, and air bubbles, all influenced by temperature and mechanical forces. By understanding these technical aspects, baristas can consistently create the perfect microfoam for espresso-based beverages, enhancing both their visual appeal and taste experience.

The science behind milk frothing continues to evolve, with ongoing research into the molecular behavior of different milk components and how they interact during the steaming process. This knowledge not only helps improve traditional dairy milk frothing but also informs the development of better non-dairy alternatives that can produce comparable results.

Mastering milk frothing requires both technical knowledge and practical experience. By applying the scientific principles outlined on this website, anyone can improve their milk steaming technique and create beautiful, delicious espresso beverages with perfect microfoam.

Breakdown of milk's components and their role in frothing.

How proteins change during the heating process.

The physics of proper steam wand placement.

How temperature influences milk protein behavior.

Differences between microfoam and macrofoam.

Summary of scientific principles for perfect frothing.